- Markets

- Products

- Services

- News

- Tools & Resources

- About Nexans

- Search

- Contact us

- Compare

- Sign in

Innovation

Nexans recognized for its commitment to sustainable innovation with CABLELOOP recycling service

Dec 4, 2024

Nexans is accelerating its sustainability strategy and has made a commitment to the circular economy with an innovative recycling service, CABLELOOP, dedicated to electrical cables.

The CABLELOOP service has distinguished itself by its sustainable dimension, winning several awards for its responsible approach to benefiting the entire cable industry and preserving natural resources. This recognition rewards Nexans' strategy of offering sustainable innovations in line with the Group's E3 management model, which combines economic, environmental and social value creation.

The CABLELOOP service received various awards for 2024

- Winner of the “Trophées Marketing B2B 2024” in the “Positive Impact” category with the GOLD AWARD, organized by Adetem ;

- 2024 “Pépite” prize in the “Réussir avec un marketing responsable” Trophy, co-organized by ADEME and Transformation Positive.

Anticipating future metal shortages by recycling today's cables

Worldwide copper consumption in all sectors has more than doubled in the last 25 years, reaching 30 million tons in 2020, and could rise to 40 million tons by 2030. With electrification at the heart of the global fight against global warming, we're facing a growing need for metals. We are entering a new era of scarcity and tension for these raw materials, as world production, estimated at 33 million tons by 2030, will not be able to cover this demand. We must act urgently to do better, with less.

Recycling therefore appears to be an essential solution for anticipating future shortages while reducing our environmental impact. To cope with the increase in future demand, Nexans has developed a cable recycling service based on an innovative circular economy system. A virtuous model serving the decarbonization challenges of both customers and the cable industry.

Creating a new, responsible cable ecosystem through sustainable innovation

CABLELOOP is a turnkey recovery solution, from the collection of cable waste to transportation to our recycling center, right through to the transformation of waste into recycled raw materials. Based on a transparent financial recovery formula, customers sell their end-of-life cables to Nexans:

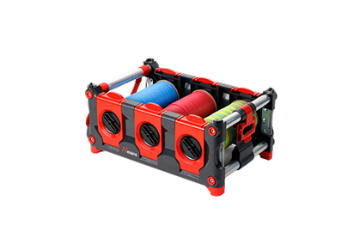

- CABLELOOP Professionnels: designed for electricians, customers can visit their nearest distributor to weigh and hand in their cables via an innovative connected terminal;

- CABLELOOP Entreprises: for key accounts, customers have access to a digital platform with a personalized portal to manage their operations 24/7, enabling full traceability of the entire processing chain.

Once collected, cable waste is recovered from end to end in France, at our “RecyCâbles” recycling center in Noyelles-Godault. Created in 2008 as a joint venture with SUEZ, RecyCâbles processes up to 36,000 tons of cables a year. Thanks to a 100% controlled recycling process and cutting-edge technology for sorting, crushing and recycling cables, we are able to recover over 18,000 tons of metal a year. In addition to guaranteeing product traceability, local processing avoids the massive export of waste from France.

By recycling their cables with CABLELOOP, Nexans' customers and partners are at the heart of a new virtuous loop promoting the circular economy, and in which today's used cables will be used to produce tomorrow's Nexans cables.

Learn more about this:

Objective: ensure the production of tomorrow's recycled, low-carbon cables

Nexans already recycles its own production waste, for a total annual volume of over 40,000 tons. With CABLELOOP, an additional 800 tons of cable scrap will be collected for recycling as early as 2025.

With its model of vertical integration of metallurgical activities, Nexans is the only industrial manufacturer to control the entire value chain of its cable production. Thanks to its foundry in Lens, the only copper foundry in France, Nexans has a major advantage in securing its cable production over the long term: upstream, thanks to supply contracts with partners, and downstream, with the recycling of its own waste and that of its customers. Nexans' ambition is to integrate at least 30% recycled copper in the production of new electrical cables by 2030, to eventually create the next generation of recycled, low-carbon cables.

related news

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania