- Markets

- Products

- Services

- News

- Tools & Resources

- About Nexans

- Search

- Contact us

- Compare

- Sign in

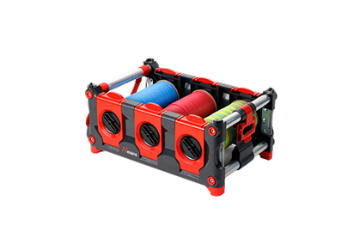

CRYOFLEX® Transfer Lines type 60/110 (DN50)

CRYOFLEX® Transfer Lines type 60/110 (DN50)

Nexans CRYOFLEX® are flexible junction-free and vacuum-insulated cryogenic piping systems made to ease the design, installation and operation of static industrial cryogenic infrastructures. They are applicable to all cryogenic fluids and process temperatures starting from 4K.

Read moreDescription

Description

Standards

-

Product2014/68/EU; ASME on request; DIN EN ISO 10380

Key benefits

- Leaner Design: Cryogenic network simplification by 75% : flexible and continuous design: no joint, no below, no elbow needed.

- Swift installation: Unroll. Plug. Operate.lines fully prepared in factory delivered at length, terminated, tested and ready to operate and No onsite welding nor X-ray analysis needed!

- Boil-off reduced by up to 45%:: High-vacuum insulation, No heat inleak from intermediate junctions, no hot spots

- Maintenance free 5 years: long lasting high-vacuum <1E-4 mbar at room temperature

- Safety: No cold spot, no icing, Double containment, Detection of vacuum loss"

Construction

Nexans CRYOFLEX® is a pipe-in-pipe construction made of two helically-corrugated stainless steel tubes, helical corrugation provides flexibility with limited impact on pressure drop.

High performance thermal insulation is achieved between process and outer tubes from combined action on heat radiation, conduction and convection:

- Multilayer insulation material: multiple layers of highly reflective film separated with spacer fleece is lapped on process tube to reflect heat radiation outside of the construction

- High vacuum is generated in the annular space and stabilized with molecular sieves and chemical getter to prevent heat convection.

- Low loss spacer minimize contact area and subsequent heat conduction between outer and process tubes

An outer PE jacket serves as mechanical protection. (Optional low fire hazard or PE-jacket free configurations).

All Nexans CRYOFLEX® lines integrate a pumping module equiped with burst disks, a pumping port and a vaccum-sensing port.

Nexans CRYOFLEX® are available from DN20 to DN200. please contact us for product details for configurations larger than DN50 or special constructions

Components

|

LN2 |

LNG |

LOX |

LH2 |

LHe |

|

|

Standard terminations |

+ |

|

|

|

|

|

Screw-type Couplings 28/25 and 34/32 |

|

|

|

|

|

|

Johnston couplings |

+ |

+ |

+ |

+ |

+ |

|

T pieces |

|||||

|

Non Insulated |

+ |

|

|

|

|

|

Vacuum Insulated |

+ |

+ |

+ |

+ |

+ |

|

Mechanical Degassing |

|||||

|

Non insulated |

+ |

|

|

|

|

|

Vacuum Insulated |

+ |

|

|

|

|

|

Manual cold valve |

|||||

|

Non insulated |

+ |

|

|

|

|

|

Vacuum Insulated |

+ |

+ |

+ |

+ |

+ |

|

Safety valve |

+ |

+ |

+ |

+ |

+ |

|

Vacuum lock |

+ |

+ |

+ |

+ |

+ |

|

Vacuum monitoring |

+ |

+ |

+ |

+ |

+ |

Customer Value in Comparison to Rigid Tubes

|

Rigid tubes |

Nexans CRYOFLEX® Transfer Lines |

|---|---|

|

|

Characteristics

Characteristics

Construction characteristics

Construction characteristics

Dimensional characteristics

Dimensional characteristics

Electrical characteristics

Electrical characteristics

Mechanical characteristics

Mechanical characteristics

Usage characteristics

Usage characteristics

Resources

Resources

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania